Your Guide to Stainless Steel Rust Remover

Your Guide to Stainless Steel Rust Remover

It's a frustrating but common sight in any commercial kitchen or facility: rust spots showing up on equipment that's supposed to be "stainless." The hard truth is that even high-quality stainless steel can rust if its protective layer gets compromised. When that happens, oxygen and moisture react with the iron in the steel, and the corrosion process begins.

Why Even Stainless Steel Rusts

The term "stainless" steel is a bit of a misnomer; a more accurate way to think of it is "stain-resistant." Stainless steel gets its protective power from chromium, which forms a thin, invisible, passive layer of chromium oxide on the surface. This microscopic film is what shields the steel from corrosion.

But when that protective barrier gets scratched, worn down, or chemically damaged, rust can—and will—form.

For busy restaurants and janitorial teams, a few common culprits are usually responsible for this breakdown. Pinpointing them is the first step toward not just removing the rust, but stopping it from coming back.

Common Causes of Rust in Commercial Settings

Daily operations can accidentally create the perfect conditions for rust. Harsh chemical sanitizers, especially those containing chlorides (like bleach), are notorious for eating away at that protective chromium oxide layer. Even plain old tap water, particularly hard water with a high mineral content, can leave behind deposits that degrade the surface over time.

Physical damage is another huge factor. Using abrasive tools like steel wool or wire brushes for cleaning can carve deep scratches into the surface. These tiny grooves trap food particles and moisture, creating a perfect breeding ground for rust.

Then there's simple contact with regular carbon steel. A stray screw, a cheap scouring pad left on a wet prep table, or even dragging a regular steel pot across the surface can transfer iron particles. This is called ferrous contamination, and it's a fast track to corrosion.

The most overlooked cause of rust is often simple contamination. A regular steel tool left on a stainless prep table overnight can leave a perfect rust bloom by morning, proving that even brief, indirect contact can compromise the surface.

Fortunately, figuring out the cause helps you choose the right stainless steel rust remover. For minor, superficial rust stains on a prep table, a gentle approach is all you need. But for more advanced corrosion on an industrial dishwasher or outdoor equipment, you'll need something with more muscle.

The key is matching the solution to the problem, just like you wouldn't use a heavy-duty degreaser on a delicate surface.

- For light rust on food-contact surfaces: Your best bet is one of our specialized Food-Safe Cleaners. They're formulated to be effective without leaving behind any harmful residues.

- For severe corrosion on non-food equipment: Our Heavy-Duty Removers have the industrial strength needed to dissolve stubborn rust and restore the metal's integrity.

Here's a quick reference to help you decide on the best approach for your specific situation.

Quick Guide to Rust Remover Types

This simple comparison will help you choose the right approach for your stainless steel cleaning needs.

| Remover Type | Ideal For | Food-Safe Option | Application |

|---|---|---|---|

| DIY Natural Solutions | Very light surface stains, routine cleaning, and preventive maintenance. | Yes | Apply paste (baking soda, vinegar), let sit briefly, then scrub gently. |

| Commercial Cleaners | Moderate to heavy rust on food-contact surfaces and general equipment. | Yes (specialized) | Spray-on, wipe-off formulas for quick and compliant cleaning. |

| Heavy-Duty Removers | Severe corrosion, deep pitting, and rust on non-food contact equipment. | No | Gel or liquid formulas that require dwell time before rinsing. |

Choosing the right tool for the job makes all the difference. By understanding what causes rust in your facility, you can not only remove it effectively but also take smart steps to prevent it from returning, saving you time and protecting your valuable equipment.

Choosing the Right Rust Remover

Picking the right stainless steel rust remover isn't about grabbing the strongest bottle you can find. In a commercial kitchen or a public-facing facility, using the wrong formula can damage your equipment, create safety compliance headaches, or just flat-out fail to work. The real key is matching the cleaner's chemistry to how bad the rust is and what kind of surface you're cleaning.

Rust removers aren't all the same. They generally fall into one of three buckets based on their pH level: acid-based, alkaline, and neutral. Each one has a specific job, whether you're dealing with a few rust spots on a food prep counter or heavy corrosion on an outdoor handrail.

Making the right call from the start protects your gear and keeps your workspace safe and compliant.

Match the Formula to the Job

Think of rust removers like tools in a toolbox—you wouldn't use a sledgehammer to hang a picture. For really heavy, stubborn rust on surfaces that don't touch food, like a loading dock gate or a metal support beam, a powerful acid-based cleaner is your best bet. These formulas cut through deep corrosion fast, saving a ton of time and elbow grease.

But that same aggressive acid would be a huge mistake on a commercial sink or a stainless steel prep table. For any surface that comes into contact with food, a food-safe, neutral pH formula isn't just a good idea—it's a requirement.

That's exactly where our Product B - Neutral Food-Safe Formula shines. It's engineered to be tough on rust without risking the safety of your food prep areas. You get rid of the stains and stay fully compliant with health and safety standards.

The most common mistake we see is people using a one-size-fits-all approach. A rusty dishwasher rack needs a completely different treatment than a corroded public handrail. The dishwasher rack absolutely requires a food-safe solution, while the handrail can handle a more powerful, industrial-strength formula.

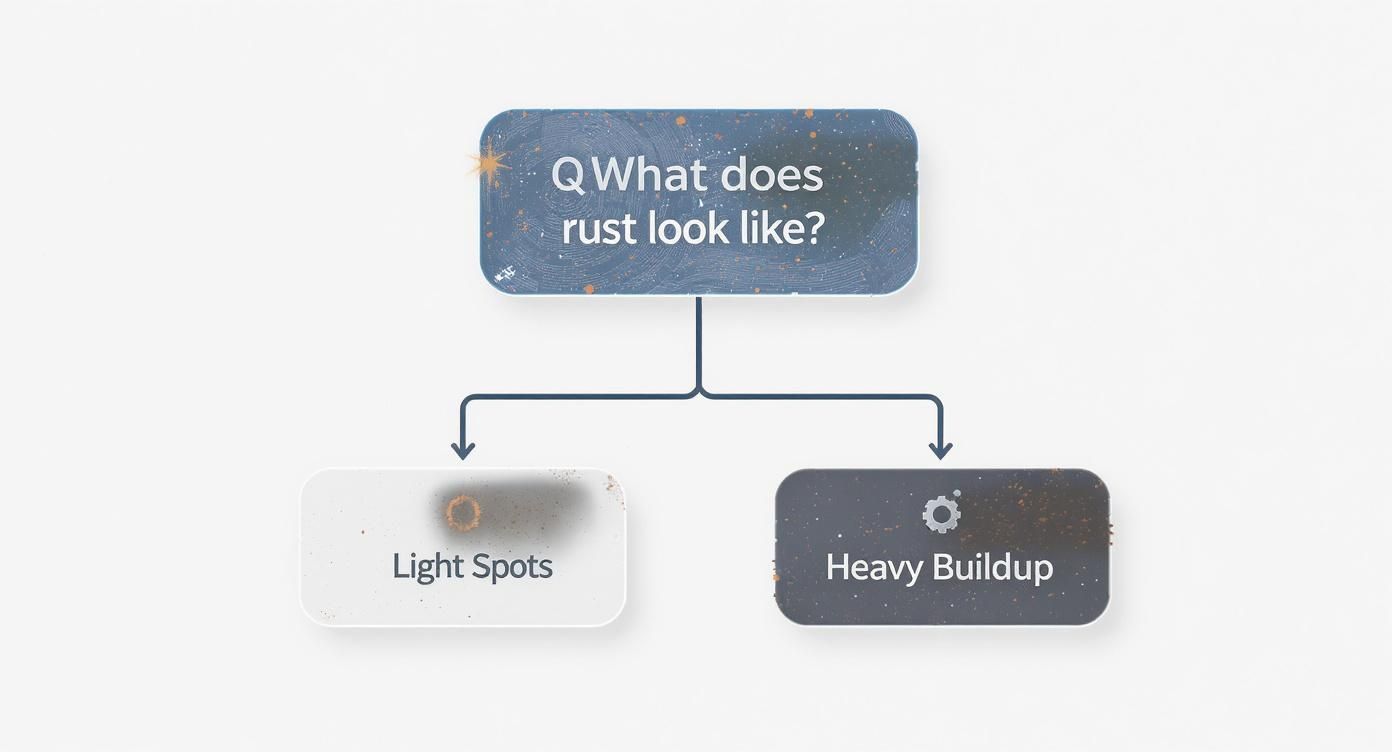

To make it even simpler, just start by looking at the rust itself.

This visual guide is the first step in figuring out which type of stainless steel rust remover you need, based on what you see in front of you.

As you can see, light, surface-level spots can be handled with a gentler approach. Deep, heavy buildup, on the other hand, points you toward a more heavy-duty product right from the get-go.

Understanding the Chemical Differences

Knowing the "why" behind each type of rust remover helps you choose with confidence. Here's a quick rundown of what makes them different and where each one really shines:

- Acid-Based Removers: These are the heavy hitters. They usually contain phosphoric or oxalic acid to chemically dissolve rust (iron oxide) in a hurry. They're fantastic for restoring heavily corroded parts that aren't in a sensitive area, but be warned—they can etch or discolour delicate stainless finishes if left on too long.

- Alkaline Removers: These products work differently. Instead of harsh acids, they use a process called chelation to lift the rust right off the surface. They're generally much safer on the base metal and are a great middle-ground option for moderate rust on equipment where you need to preserve the original finish.

- Neutral pH Removers: This is your safest bet for both the user and the surface. They are the go-to for food-contact surfaces, high-end appliances, and routine maintenance. While they might need a bit more dwell time or a little scrubbing, their non-corrosive nature makes them perfect for sensitive applications. Our Product B - Neutral Food-Safe Formula is a prime example.

The growing demand for these different formulas is no surprise. The rust remover market in North America was valued at around USD 551 million and is expected to grow by about 4.6% annually, driven by maintenance needs across all major industries. In places like California, alkaline rust removers hold a massive 43.7% market share because of strict environmental rules that favour safer chemicals. At the same time, fast-acting acid-based removers are still dominant in the state's huge automotive and aerospace sectors, proving there's a clear need for different formulas for different jobs. You can discover more insights about these market trends.

Ultimately, choosing the right stainless steel rust remover is a strategic decision. By looking at how bad the rust is, identifying the surface you're cleaning, and understanding the chemistry, you can get your equipment looking its best safely and efficiently.

How to Safely Remove Rust from Stainless Steel

Alright, you've spotted the rust and picked your product. Now it's time to get hands-on and bring that stainless steel back to life. This isn't just about making it look good; it's about doing the job safely to protect your gear, your team, and your customers.

Let's skip the generic advice and get right into the professional techniques that give you perfect results without creating bigger problems, like scratches or chemical residues in a food prep area. How you handle this process makes all the difference.

Prepping Your Workspace for Safety and Success

Before you even think about opening a bottle of rust remover, your first move is to set up a safe, controlled work area. A few minutes of prep work here prevents accidents and ensures you get the job done right the first time, saving you from a world of headaches later.

First things first, get some air moving. Many commercial-grade rust removers give off fumes, so good ventilation is non-negotiable. Open up windows and doors, or kick on the exhaust fans to create some solid airflow. This is a basic step to protect the respiratory health of everyone in the vicinity.

Next, gear up. The right Personal Protective Equipment (PPE) is a must. At a bare minimum, you'll need:

- Chemical-resistant gloves: Keep the product off your skin. Simple.

- Safety glasses or goggles: You only get one pair of eyes. Protect them from splashes.

Don't forget to protect the surrounding surfaces, too. If you're working on a prep table, lay down some plastic sheeting or old towels to catch drips that could stain or damage countertops, floors, or nearby equipment.

The Non-Negotiable Spot Test

If you take one thing away from this guide, let it be this: always, always test your product on a small, hidden area first. I don't care how well you know a product; different grades and finishes of stainless steel can react in weird ways. This quick check can save you from a costly, irreversible mistake.

Find an inconspicuous spot—the back of an appliance leg, the underside of a shelf—and apply a small dab of your chosen stainless steel rust remover, like our Featured Product C. Follow the directions just like you would for the main event, let it sit for the recommended time, then wipe and rinse it clean.

Look closely for any discolouration, etching, or dulling of the finish. If it looks good, you're clear to proceed with confidence.

Think of the spot test as your insurance policy. Taking two minutes to check a hidden corner can save you from ruining a thousand-dollar piece of equipment. It's a step no professional ever skips.

Applying the Rust Remover with Finesse

With your area prepped and your product tested, it's showtime. Technique is everything here. You want to work with the grain of the steel, never against it.

Look closely at the stainless steel surface. You'll see very faint lines running in one direction—that's the grain. Scrubbing in the same direction helps prevent tiny scratches and leaves a clean, uniform finish.

Follow these best practices for application:

- Use a Non-Abrasive Applicator: Step away from the steel wool or harsh scouring pads. Grab a soft cloth, a microfiber towel, or a non-abrasive scrubbing pad. These will lift the rust without scratching the metal underneath.

- Apply Evenly: Put the rust remover on your cloth or pad first, not directly on the steel. This gives you more control and prevents you from using too much product. Work it onto the rusted spot in smooth, even strokes, following that grain.

- Let It Dwell: Most chemical removers need a bit of time to do their thing. Let the product sit for the duration specified on the label. This dwell time allows the active ingredients to break down the rust, meaning less elbow grease for you.

The Critical Rinse and Neutralization Phase

Getting the cleaner off is just as important as putting it on, especially in any kitchen or food-service environment. Leftover chemical residue is a major food safety risk and can even cause rust to come back faster.

Once the dwell time is up, rinse the area thoroughly with clean water. Use a fresh, damp cloth to wipe away every last trace of the rust remover and the dissolved gunk. You'll probably need to rinse your cloth and wipe the surface a few times to get it all.

For any food-contact surface, this step is non-negotiable. After the first rinse, wash the area with a mild detergent and water, then follow up with a final clear-water rinse. This neutralizes any leftover cleaner.

Finally, dry the surface completely with a clean, soft towel. Leaving stainless steel wet is like sending an open invitation for new rust spots to form. A quick, thorough drying protects your hard work and your equipment.

Commercial Removers vs DIY Solutions

When you spot a few rust marks on your stainless steel, it's tempting to hit the internet for a quick pantry fix. We've all seen the hacks using vinegar, baking soda, or lemon juice. And sure, for a tiny, superficial stain on your fridge at home, they might do the trick.

But in a professional setting? A commercial kitchen or a high-traffic facility isn't dealing with minor cosmetic issues. You're up against tougher, more embedded rust that demands a reliable, repeatable solution every single time. A homemade paste might feel like you're saving a few bucks, but the results are often a gamble.

The Hidden Risks of Homemade Solutions

The biggest issue with DIY methods is the complete lack of control. Mixing vinegar and baking soda gives you a mild acid, but the concentration is anyone's guess. This can lead to blotchy, uneven cleaning, or it might just fail to remove the rust at all.

Even worse, if you leave an acidic solution like straight vinegar on a surface for too long, you can cause pitting. These are tiny, permanent holes that eat into the steel, ruining the finish and creating brand new hiding spots for bacteria and future rust. For any professional operation, that kind of inconsistency is a massive liability.

A common mistake is treating all rust the same. A DIY paste might lift a light rust bloom caused by a wet can, but it stands no chance against the stubborn corrosion found on a dishwasher rack that endures daily chemical exposure and high heat.

On top of that, homemade solutions come with zero guarantees of food safety. There are no certifications ensuring your kitchen concoction is safe for food-prep surfaces after you rinse it off. In any environment governed by health codes, that's a risk you just can't afford to take.

The Reliability of a Formulated Stainless Steel Rust Remover

This is where a commercial-grade stainless steel rust remover really proves its worth. These aren't just random ingredients mixed in a bowl; they are scientifically formulated by chemists to deliver specific, repeatable results. When you use a professional product, you're not guessing. You're using a tool engineered for the job.

The advantages are clear and immediate:

- Predictable Performance: Formulated removers work the same way every time, getting rid of rust without damaging the metal underneath when you follow the directions.

- Certified Safety: Many professional products are NSF-certified, which is your guarantee that they're safe for food-contact surfaces after proper rinsing. Our lineup of Food-Safe Cleaners provides this critical compliance.

- Time Savings: In the professional world, time is money. A commercial remover works faster and more effectively, which translates directly into labour savings. No more trial and error.

We're seeing a bigger industry shift towards these kinds of specialized, reliable solutions. Neutral rust removers, for instance, are seeing a huge surge in demand in California's high-tech sectors for maintaining delicate equipment. The global market for these gentler, more precise formulas is projected to climb from USD 850 million to around USD 1.3 billion in the next several years. Why? Because they offer effective cleaning without the risks of harsh, unpredictable chemicals. Learn more about the growth of specialized rust removers.

Ultimately, choosing a commercial stainless steel rust remover is an investment in efficiency, safety, and quality. While a DIY approach might save you a few cents on ingredients, the potential costs of damaged equipment, failed health inspections, and wasted labour make a professional product the only smart business decision.

How to Prevent Rust on Stainless Steel

You've put in the work to get the rust off. The last thing you want is for it to come roaring back.

This is where you shift your focus from removal to prevention. It's the single best way to protect your equipment and your investment. A consistent maintenance plan isn't just a one-time fix; it's a long-term care strategy that will save you a ton of time and labour costs down the line.

It all comes down to building simple, proactive habits into your team's daily workflow. This isn't about adding complicated steps. It's about making small adjustments that have a huge impact on the lifespan of your stainless steel.

Establishing a Proactive Maintenance Routine

The best rust prevention strategy is one you don't even have to think about. By making these practices a standard part of your daily closing procedures, you create an environment where rust can barely get a foothold.

Your routine should centre on a few key actions:

- Daily Wipe-Downs: At the end of every single shift, wipe down all stainless steel surfaces with a clean, damp cloth and then—this is the critical part—dry them completely. This gets rid of the food particles, moisture, and corrosive bits that build up during service.

- Avoid Harsh Chemicals: Make sure your team knows to steer clear of cleaners containing chlorides, bleach, or abrasive powders. These are notorious for stripping the steel's protective layer, leaving it wide open to corrosion.

- Use Soft Materials: Stick to non-abrasive tools like microfibre cloths or soft sponges. Steel wool, wire brushes, and scouring pads will carve micro-scratches into the surface that are perfect little traps for moisture, basically inviting rust to move in.

A simple end-of-day routine is your first line of defence. Wiping down and drying a prep table takes less than a minute, but it eliminates the two primary ingredients rust needs to form: moisture and contaminants.

The Science of Passivation and Protection

When you use a stainless steel rust remover, you're stripping away the iron oxide. But what happens next is just as important. You need to help the steel rebuild its natural protective barrier, a process known as passivation.

Passivation is just the spontaneous formation of a non-reactive film—the chromium oxide layer—that shields the metal from corrosion. While this happens naturally when stainless steel is exposed to air, some products can speed this process up and make the shield even tougher.

This is where a dedicated protective polish comes into play. After cleaning, applying a high-quality polish does two things. First, it helps restore that passive layer. Second, it leaves behind a thin, invisible film that acts as a physical barrier against moisture, fingerprints, and corrosive elements.

For instance, our Product D - Protective Polish is specifically designed to create this protective shield. Think of it like waxing a car; you're not just making it shine, you're adding a layer of defence against the elements. Regular application keeps your equipment looking pristine and significantly extends its lifespan by stopping rust before it can even think about starting.

Keeping an Eye on Environmental Factors

Sometimes the threat comes from the air itself. High humidity, salt in the air (if you're in a coastal area), and even hard water can put corrosion into overdrive.

Being mindful of these factors helps you tailor your prevention strategy. In a high-humidity kitchen, for example, ensuring you have proper ventilation and are extra diligent about drying surfaces becomes absolutely critical.

The demand for effective rust prevention products is only growing, especially in industrial centres. In California, for example, the need to maintain a huge amount of aging infrastructure has driven up the consumption of rust removers. The global market, valued at around USD 593.64 million, is projected to nearly double by 2032, which shows a worldwide focus on making assets last longer. This trend just highlights how crucial proactive maintenance and the right products are for protecting your valuable equipment. You can read the full research on rust remover market dynamics.

By combining a solid daily cleaning routine with the periodic use of a protective polish, you shift from reacting to problems to actively preventing them. This simple, two-pronged approach is the professional standard for keeping stainless steel truly stainless.

Your Top Questions About Stainless Steel Rust Answered

Even with the best game plan, questions always pop up when you're staring down a rust problem for the first time. We get calls about this all the time, so we've put together answers to the most common queries we hear from kitchen managers and cleaning crews. This should help you handle any rust situation like a pro.

Can I Use a Rust Remover on a Commercial Grill or Prep Table?

Yes, but this is one area where you absolutely cannot cut corners. You must use a stainless steel rust remover specifically rated as food-safe or NSF-certified. These formulas are engineered to knock out rust without leaving behind any sketchy chemical residues that could compromise food safety.

The product you choose is only half the battle; how you use it is just as critical. Follow the manufacturer's directions to the letter, especially the final rinse step. This isn't just about getting the cleaner off—it's about making sure the surface is completely neutralized and safe for direct food contact. Our own Food-Safe Rust Remover Product is formulated and certified precisely for these sensitive jobs.

A common mistake we see is people thinking "natural" DIY solutions are automatically food-safe. While vinegar or lemon juice are edible, their acidic nature can cause microscopic pitting in the steel. This creates tiny new hiding spots for bacteria. A certified commercial product cleans the rust and leaves the surface intact and compliant.

Will a Rust Remover Scratch My Stainless Steel Appliance?

The right product won't, but the wrong technique most certainly will. A good chemical rust remover is designed to dissolve the iron oxide (the rust itself) without harming the stainless steel underneath. The real danger comes from the tools you pair it with.

Never, ever use abrasive materials like steel wool, wire brushes, or gritty scouring pads. They will absolutely leave scratches and permanently ruin the finish. We always tell our clients to pair a non-abrasive chemical remover, like our Featured Product C, with a soft cloth, microfibre towel, or a gentle, non-scratch scrubbing pad. And always work gently in the direction of the metal's grain—it's like petting a cat the right way—to preserve that original look.

How Do I Know If It Is Surface Rust or Permanent Damage?

Figuring out if you're dealing with a simple surface issue or deeper corrosion is the key to setting realistic expectations for the repair.

Here's a quick way to tell the difference:

- Surface Rust: This usually looks like a light, powdery brown or orange film sitting on top of the steel. It might feel a bit rough, but it hasn't actually eaten into the metal. In most cases, you can clean this away completely and restore the surface to look like new.

- Permanent Damage (Pitting): This is what you find after you've cleaned the rust away. If you see tiny pits, grooves, or a rough, crater-like texture left behind, the metal itself has been corroded. The protective chromium layer was breached, and the iron underneath has been eaten away.

While a heavy-duty stainless steel rust remover can effectively clean the rust out of these pits, the physical damage to the metal is irreversible. That's why a consistent cleaning and protection routine is so important—it stops minor surface rust from turning into a much bigger, permanent headache.

For a complete range of professional cleaning solutions, from food-safe formulas to protective polishes, trust Chicken Pieces to supply your business. Find the perfect stainless steel rust remover for your needs by visiting our Janitorial & Sanitation Supplies section.

US Dollar

US Dollar